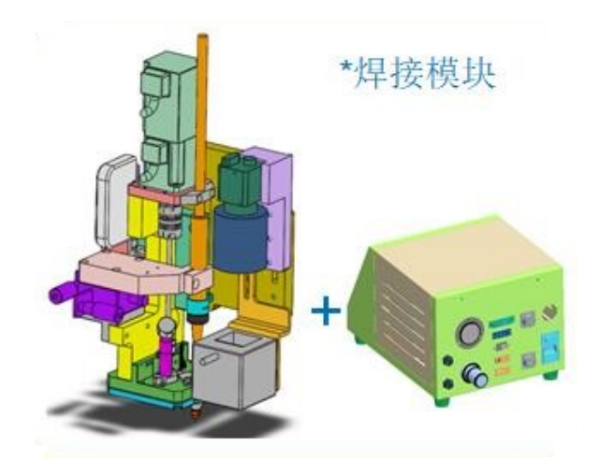

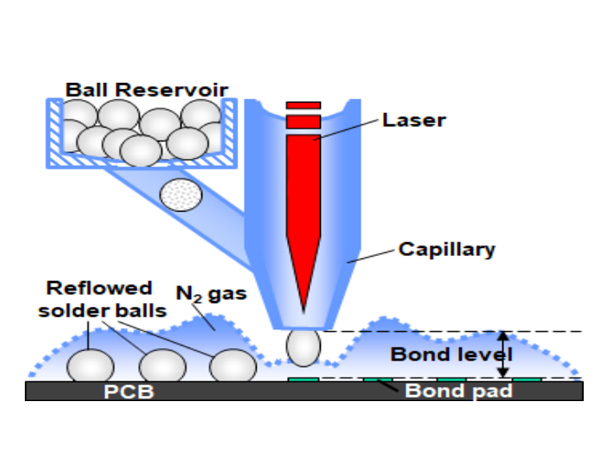

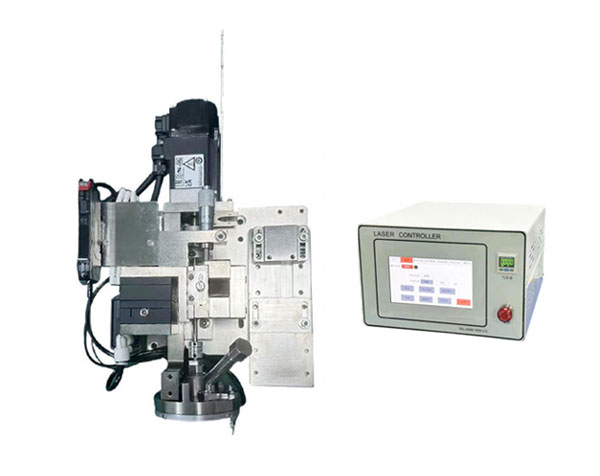

Laser solder ball welding module

It includes the installation of mechanical unit and independent electric control box. The mechanical part is installed on the z-axis mechanism of X-Y-Z platform, and the electrical is connected with the I / O communication of main console;

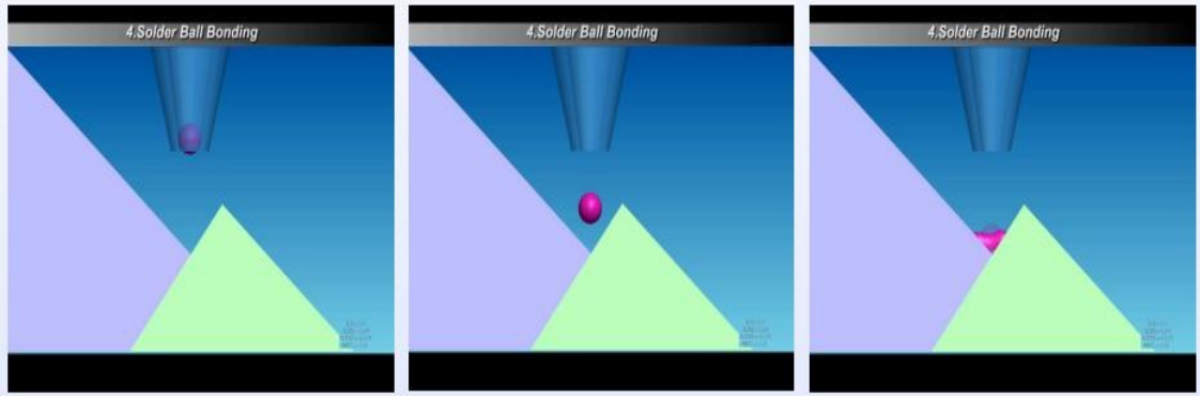

The control mode is simple. Only a few IO points can complete a series of actions such as ball dropping, laser output, ball spraying and so on.